Collaborative Design Philosophy

At Celsia, we prioritize customer collaboration to drive effective product design. By engaging early in the development process, we ensure optimal thermal performance, streamlined manufacturability, and seamless system integration—delivering solutions that meet engineering and production requirements.

Collaboration is at the core of our design philosophy. Our flexible engineering schedules allow for short-notice design consultations, video conferences, and data clarifications, ensuring seamless communication and efficient problem-solving. By being readily available, we:

- Provide readily available engineering support to accelerate design iterations.

- Enable rapid design adjustments based on performance simulations.

- Ensure continuous alignment with customer requirements throughout the development process.

Application Requirements Definition & SWaP-C Priorities

We deliver custom thermal solutions for applications in Aerospace, Defense, Telecom, Industrial and Medical Industries that thrive under the harshest conditions.

Application Examples: military land electronics, telecom infrastructure equipment, low-orbit satellites.

Understanding Size, Weight, Power, and Cost (SWaP-C) priorities and trade-offs are critical to developing thermal solutions that are properly optimized for each application. Our approach includes:

- Collaborative requirement gathering to define thermal, mechanical, and integration constraints fully.

- Tradeoff analysis to balance cooling performance, manufacturability, and cost.

- Decades of two-phase optimization experience ensures the best possible heat sink performance within size, weight, and power constraints.

Full Support for Celsia or Customer-Driven CFD Modeling

Computational Fluid Dynamics (CFD) modeling plays a critical role in heat sink/thermal solutions design. Whether using our in-house simulation expertise or working with customer-provided models, we:

- Validate thermal performance early in the design cycle.

- Identify and resolve potential issues before manufacturing.

- Provide data-backed design recommendations to optimize performance and manufacturability.

Celsia’s step-by-step custom heatsink development process delivers optimized thermal solutions from concept to mass production. As a trusted heatsink manufacturer, we work closely with customers to meet demanding thermal and mechanical requirements. Below is an overview of our process, including typical turnaround times for each step.

DESIGN PHASE TIMELINE

Define Custom Heatsink Requirements

Timeframe: A few days to a week depending on the customer’s schedule.

The first step in designing an effective custom heat sink is collecting application-specific data. If some values are unknown, estimates are acceptable.

- Application Type

- Examples: military land electronics, telecom infrastructure equipment, low-orbit satellites.

- Heat Source (for each IC that needs to be cooled)

- Power in watts (TDP).

- Size (LxW).

- Lidded or unlidded IC.

- Max Tcase or Tjunction in °C.

- Duty cycle (if applicable).

- Operating Environment

- Min/Max operating temperature (°C).

- Min/Max storage temperature (°C).

- Elevation range (above/below sea level).

- Other environmental factors: high shock and vibe environments, heat, humidity, salt spray, etc.

- Custom Heatsink Specifications

- Natural or forced convection.

- Airflow into heatsink (CFM or Velocity).

- Available space for the heatsink (LxWxD).

- Distance of heatsink relative to heat source (local or remote condenser).

- Angle of orientation range (heat source location relative to condenser).

- Rank order importance of size, weight, performance/power, and cost (SWaP-C).

- If possible, provide STEP or other CAD files.

Initial Custom Heatsink Thermal Modeling

Timeframe: A few days to a week per iteration; expect 2-4 iterations.

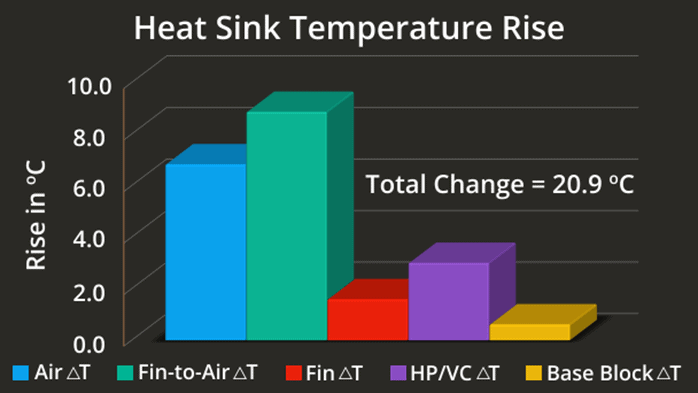

Celsia uses internal thermal simulation tools to model and compare multiple custom heat sink concepts. These models help us spot thermal bottlenecks and refine performance targets early in the design cycle.

- Video Conference

- Discuss results and assess feasibility.

- Adjust SWAP-C priorities given known constraints.

- Iterative Heatsink Refinement

- Re-run thermal models, generate reports, and refine the custom heatsink design through ongoing customer collaboration.

Heatsink CFD Development & Optimization

Timeframe: 1-2 weeks per iteration (minor tweaks faster). This step typically lasts 1-4 months, depending on the number of CFD iterations and customer response time to suggested changes.

As a custom heatsink manufacturer, we offer flexible CFD support:

- Fully Turnkey: Celsia performs all CFD analysis, including fin geometry, air velocity, and surface temperatures.

- Partial Support: We provide thermal design guidelines—such as material conductivity, fin dimensions, and pressure drop assumptions—for customer-executed simulations.

- Scope and Pricing: CFD work focuses on the custom heatsink unless broader enclosure analysis is requested. Budgetary pricing is based on simulation complexity.

Finalize Custom Heatsink Design for Prototype Build

Timeframe: 1-2 weeks if based on optimized STEP/CFD files.

While further refinement may follow prototype testing, this step includes heatsink drawings, specifications, and tolerances.